CSI Innovation Products

At Critical Systems we are always trying to “build a better mousetrap”. We talk to our customers and other industry experts and try and bring some of those innovations to market.

CSI Remote Pendant Upgrade for M217

When AMI designed the M217, they released a new pendant with very limited functionality. Customers wanted the functionality of the old M207 remote pendant while using the M217. Critical Systems developed an adapter that requires a minor rewire inside the power supply that allows our “red bullet” adapter to connect your M207 remote to your M217 power supply.

CSI Remote Mini Pendant

While customers like the functionality of the M207 remote pendant, it is large and bulky. CSI designed our CSI Mini Remote Pendant as a more compact and lightweight alternative to the M207 Remote. Our remote brings reliable technology for remote control of an orbital welder to your wrist.

The unit is engineered with a touchscreen membrane and membrane switch.

The remote provides immediate response through tactile feedback buttons.

The remote is compact and lightweight, durable, and mobile.

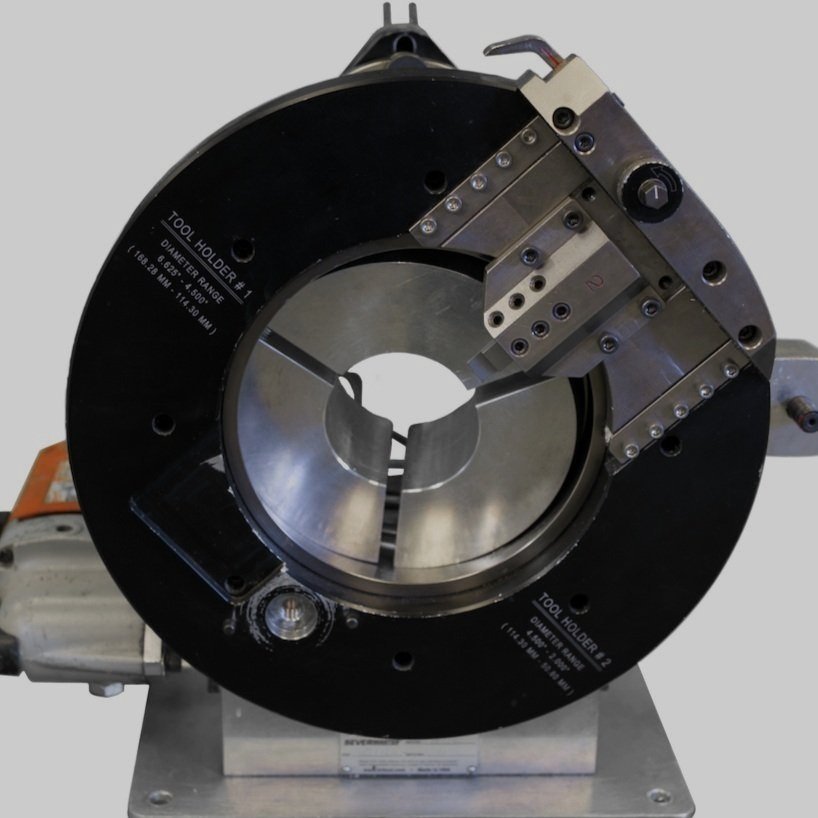

Critical Systems Extended Life Home Pin

Upgrade available for the AMI 9-750 and 9-1500 weld head

Home pin is constructed of a highly durable, temperature stable, non-conductive material with a low friction coefficient

Home pin bushing is designed for reduced wear and maximum protection of the home pin

Home switch cam button has a narrower axial engagement point, which results in a more precise home position

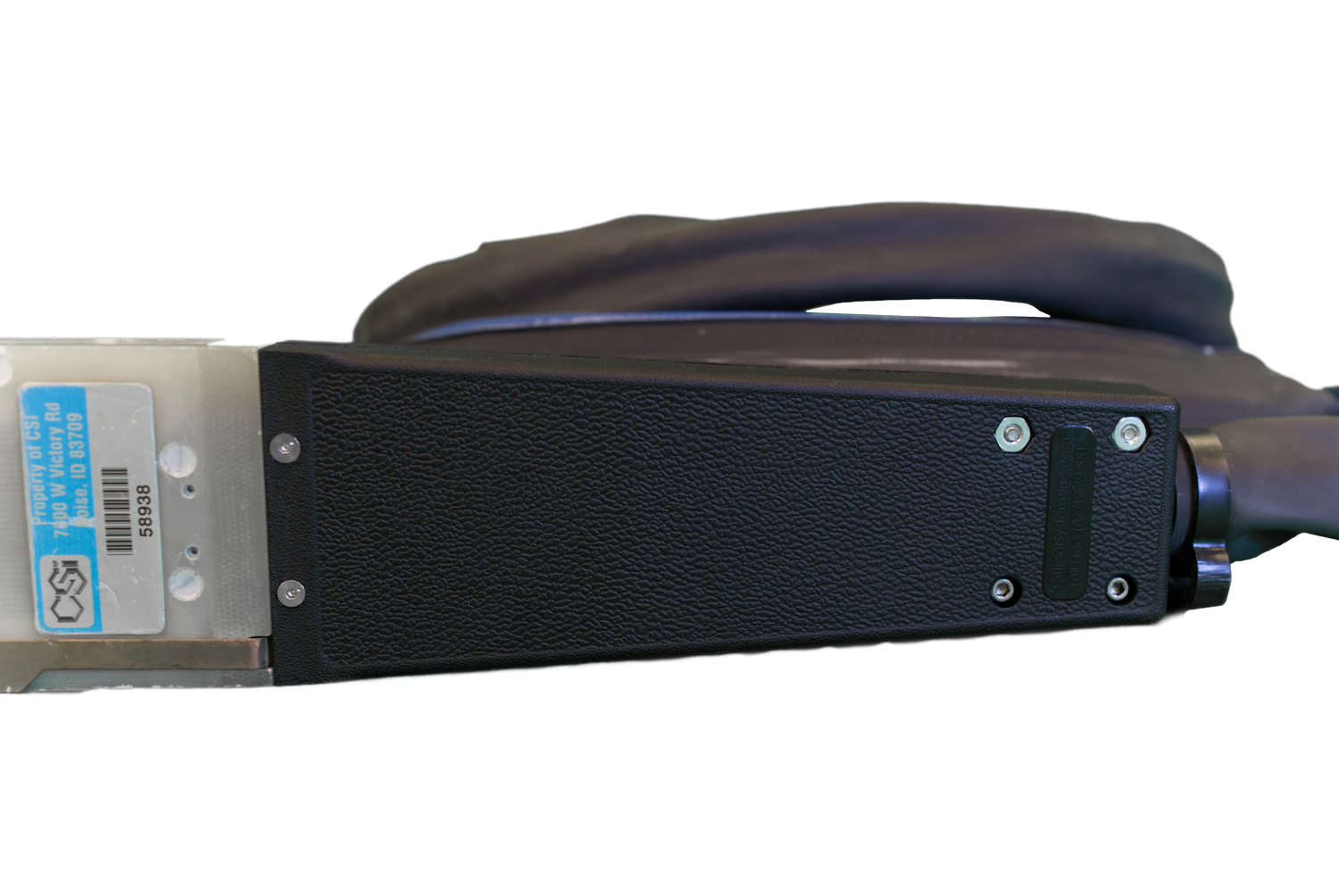

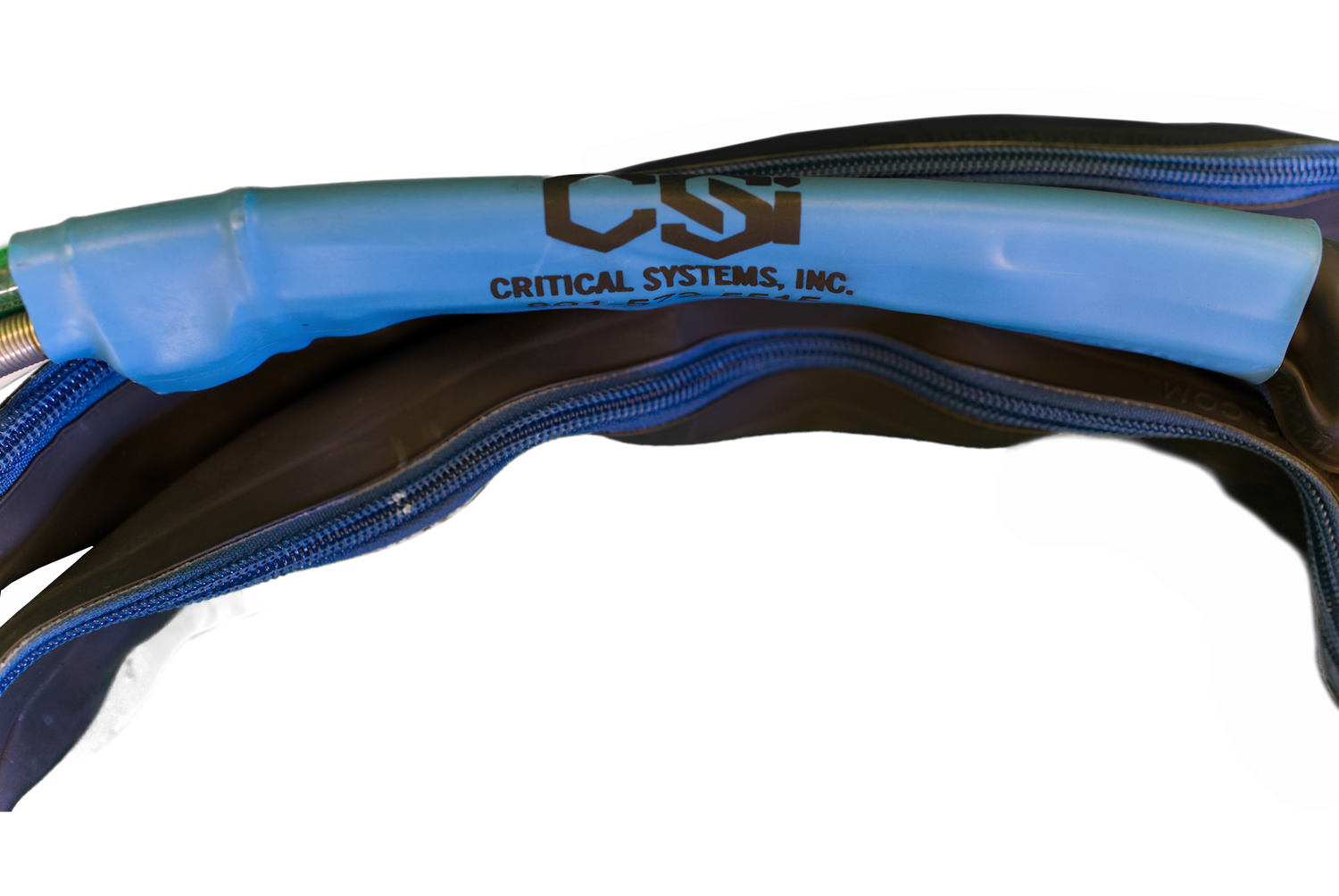

CSI Handle Sheath Upgrade

Many weld heads aren’t designed to protect from strain on weld head cables. As the leads are pulled, the conduit stretches, which eventually causes the tubing and wires to break.

CSI weld head handles incorporate a unique internal “clamp block” into a highly durable injection molded handle. The clamp block secures the cabling, while absorbing the tensile stress placed on the cables during operation.

A stainless-steel hook is also incorporated into the handle design. The hook can swing 300 degrees and can be easily removed or placed on the opposite side of the handle based on user preference.

Purge Restrictors

Easy to use.

Improves weld quality by reducing variation in purge rates

Enables 50% to 80% reduction of argon use in high purity arenas

Made out of non-volatile polyimide – no outgassing or dimensional change at high temperatures

Available for 1/4″, 3/8″, and 1/2″ Tubing

CSI Chilling Units

Designed for use with AMI 207 and AMI 217 power supplies

Run on their own standard power supply (110AC)

Results in more consistent welds, since the power isn’t pulled from power supply

Continuously cools the weld head, even after the weld is finished (manual shut-off)

Filter element is easily accessible and cleaned

Has a visual flow indicator.