Orbital Welding Consumables

Critical Systems Orbital Group has a full line of accessories for your preparation and orbital welding needs:

Tube Preparation

Durabit-1 facing blades

Durabit-2 facing blades

Durabit-3 facing blades

576 Severtool bits

572 Severtool bits

Axxair LS6872 performance sawblades

Axxair LS8054 performance sawblades

For your 9-500 fusion weld head welding needs we stock tube clamp assemblies and purge restrictors for:

1/4” tubing

3/8” tubing

1/2" tubing

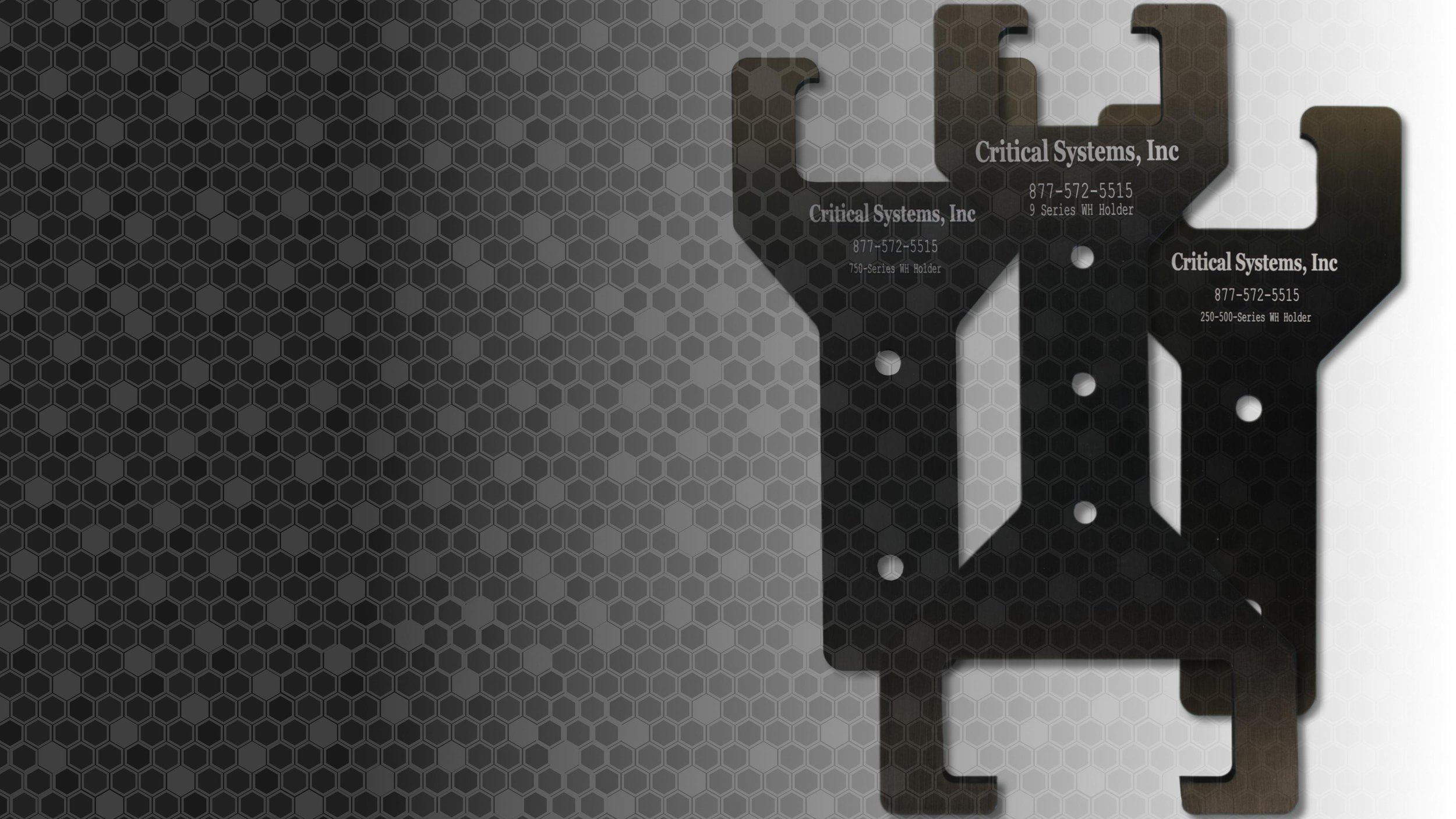

To mount your weld head for a steady weld we feature holders:

AMI 9-250 and 9-500 fusion weld head holder

AMI standard 9-Series fusion weld head holder

We feature our universal bench mount that provides a holder for both the 8 series and 9 series AMI fusion weld heads

Finally, when it’s time to weld, you need tungsten. We stock 72 different sizes of tungsten ranging from 1/4" tungsten for the AMI 9-250 all the way up to 6” for the AMI 8-6625 fusion weld head. And if we don’t have it in stock we can get it quickly and get it to your job site!